Scrollsaw Safety:

The scrollsaw is probably the safest tool in the shop , but there are still a

few safety factors to consider. I call the scrollsaw a Band-Aid tool, meaning

that the worst injury you will probably ever get can be taken care of with a

Band-Aid. Of course I can't guarantee that , but I have not heard of any major

injuries with the scrollsaw. Comparing it to any of the other saws you may have

in the shop that will take fingers off as fast as you touch the blade, the

scrollsaw just won't do that. But there are still safety factors to think

about. First thing , as with all tools, would be to think

about the clothing you wear and hair, or jewelry. A loose cuff on a long sleeve

shirt could easily be caught on the moving arm of the saw. Leaning over the saw,

long hair could be caught in the moving arm. So think about the fact that you

are using a power tool and roll those sleeves up, or button them so the are not

loose. Tie the long hair back into a ponytail to keep it out of the saw. While

scrolling there is also drilling and sanding involved, and all the safety

measures need to be followed there too. The first one is

probably the holddown clamp. Most of us, me included, take that safety feature

off the saw right away because it gets in the way. I find it to be clumsy to use

and it really is an obstruction to turning the wood and holding things. But in

reality it should be left on the saw, OSHA tells us that anyway. It does hold

the wood to the table , but your fingers can do that very easily too. The main

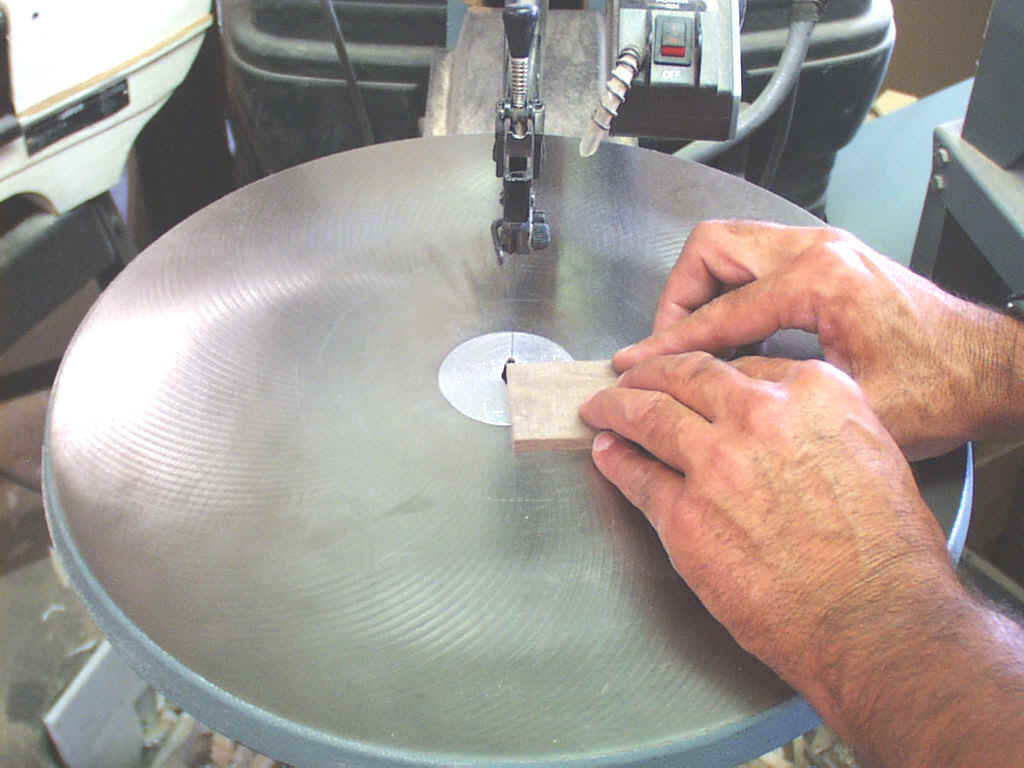

purpose I feel was to keep your fingers out of the blade. Using some good common

sense like not placing your finger in front of the blade can accomplish the same

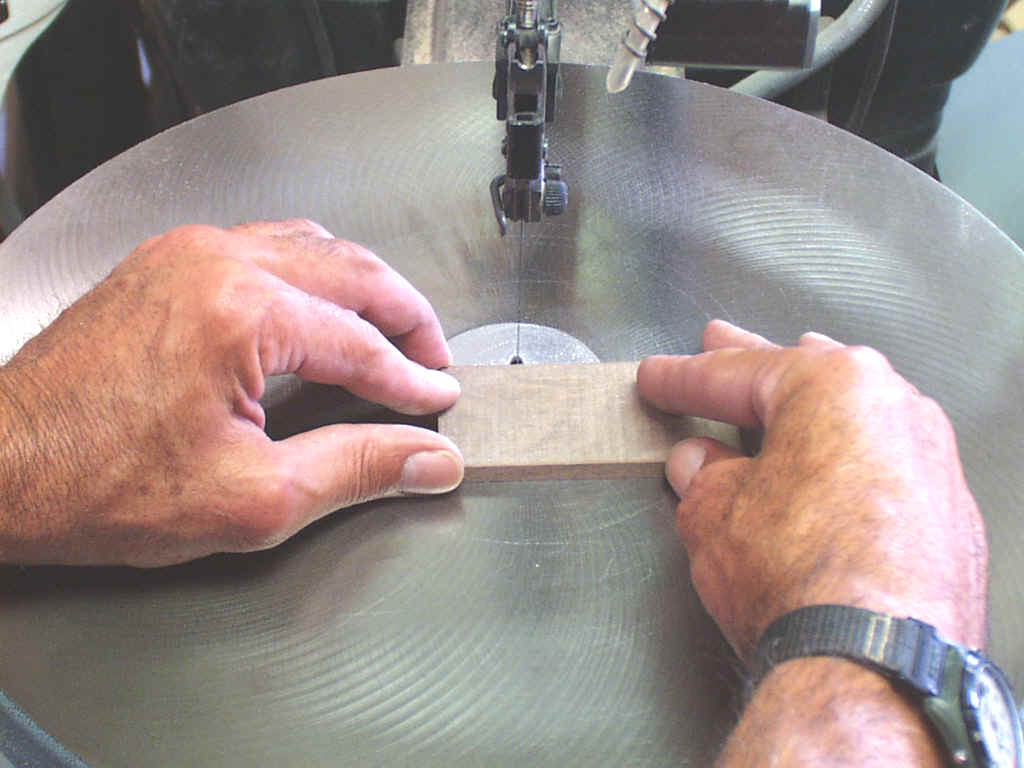

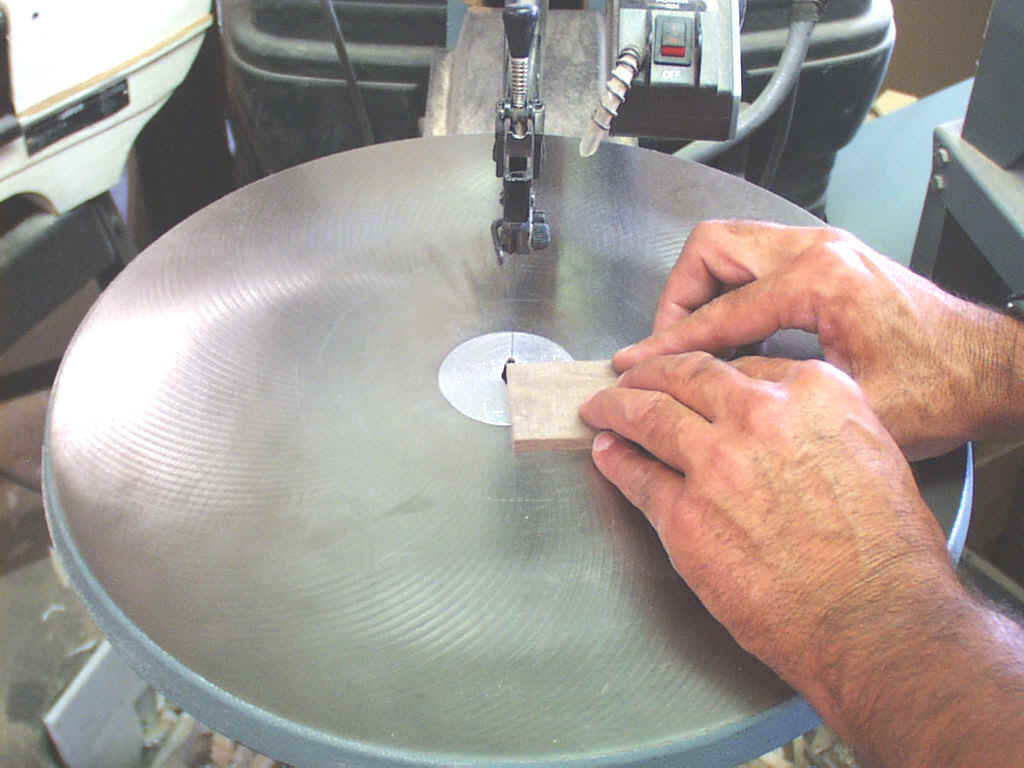

thing. As you push the wood into the blade do not place your fingers in line

with that cutting path, hold the wood on each side of the path.

Then next is to wear safety glasses. Your eyes are easy to damage and safety

should be a major concern in any work you do to protect them. A broken blade, a

chip of wood, and sawdust can all be thrown into an eye from the scrollsaw. So

eye protection is a must. I wear glasses with safety lenses so I don't really

think about adding any other protection to my eyes, but for those who do not

wear glasses, safety glasses should be a top priority on your list of safety

items for all the work in the shop.

Next would be the air quality while sawing. Believe it or not there is a lot

of very fine dust generated by the scrollsaw. After cutting for awhile you will

see the fine layer of dust on everything in the area. Now think about the fact

that you are breathing that dust in too. And remember that many of the wood

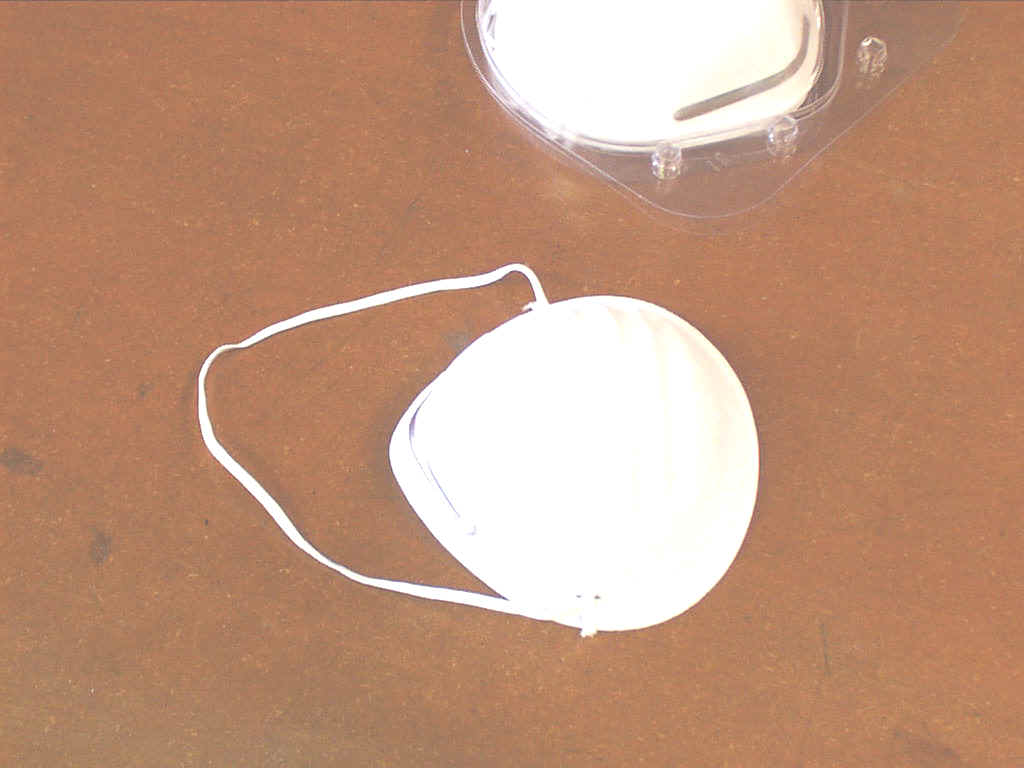

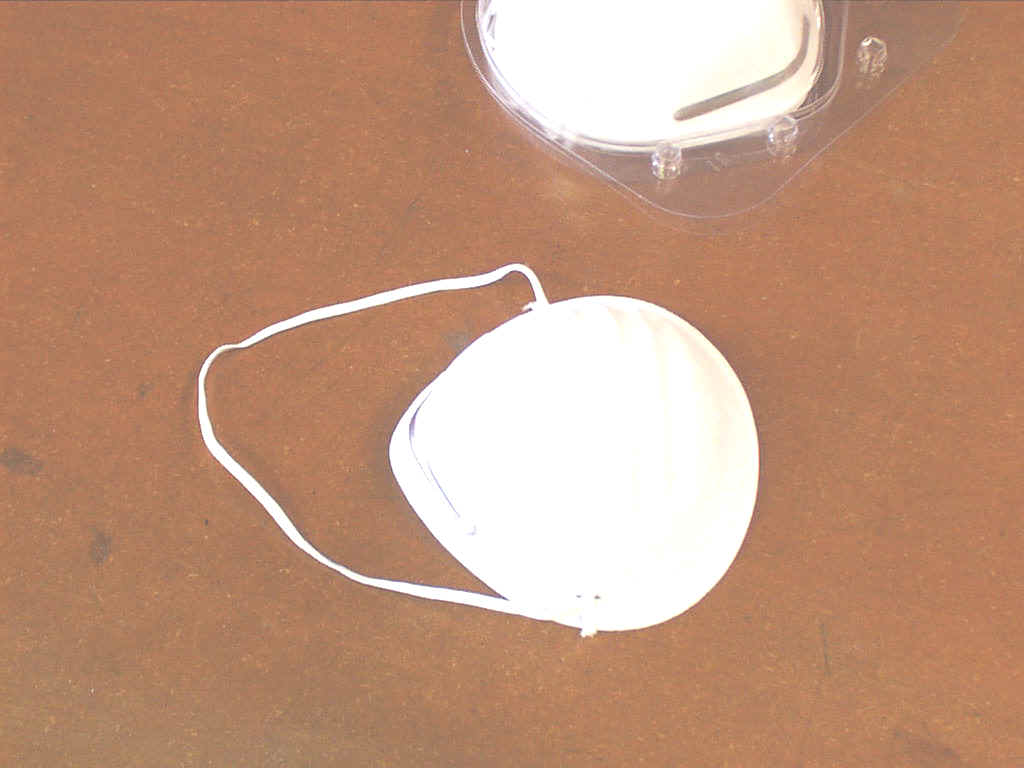

species create a dust that can is toxic. The easiest way to protect yourself is

to wear a dust mask. Some people are allergic to even the dust of certain

species of woods with just skin contact, and you think you want to breath that

into your lungs. Sure the saw has a blower on it to clear the dust from the

cutting line so you can see the line, but it blows that dust into the air.

Instead of wearing the mask there are other ways to keep your breathing air

clean. One is a fan behind you to blow the dust away from you , toward the back

of the saw. This works fine outdoors, but in a shop that airborne dust is going

to eventually going to be drawn into the fan and be mixed with your breathing

air. Is what you really did was to circulate the dust by using the fan. Another

solution that I feel works best is to use a filter to control dust. There are

good air filter systems on the market, but they are expensive. The easy way too

filter the air is using a box fan with a pleated furnace filter, on the incoming

air flow side, behind the scrollsaw. It pulls the air away from you, into the

fan behind the scrollsaw. This catches just about all the dust generated by the

scrollsaw. I have a furnace blower fan mounted in a box with the pleated filters

on two side. This unit is attached to the ceiling behind and above the

scrollsaws, and it does a good job of filtering the air. There are many other

way to filter the air, just be sure to use one.

Keeping the work area clean is not really thought about all of the

time. But for me when I get to scrolling a lot, there is a lot of scrap. A large

trash can is placed behind or to the side of the saw, so I have a place other

than the floor to throw the scrap. After some of the long sessions of scrolling

you will probably need to sweep the sawdust off the floor too. Just remember the

scrollsaw is a power tool and all of the safety precautions you use with other

tools in the shop , should be followed on the scrollsaw too. Scrollsawing can be

very relaxing, and it becomes easy to get careless unless you really think about

what you are doing.

Saftey:

Scrollsaw safety is probably the most overlooked part of using the saw. We all take the first look at the thing and figure with that little blade it sure can't hurt us a lot. Yes we might get a nick from it but other than that it has to be safe. But were we wrong. Let's look at some of the safety issues about the Scrollsaw.

To start at the beginning just try to lift the saw. It is heavy, so when setting it up right out of the box we may need to get some help. The saw is considered a somewhat portable tool, but is best used as a fixed tool. The saw can be mounted on a workbench, but usually vibration to the saw is usually increased by doing this. The best thing is to mount the saw on a stand designed for that saw. There are plans available for mounting the saw to, but beware. The saw as we know is heavy, and once mounted to a stand all of the weight is at the top. This makes the saw on the stand top heavy, so it can be easily tipped over. Any stand that you mount the saw on, make sure after mounting that it is stable. Another note is that a 3 legged stand will sit firmer and reduce vibration with the saw.

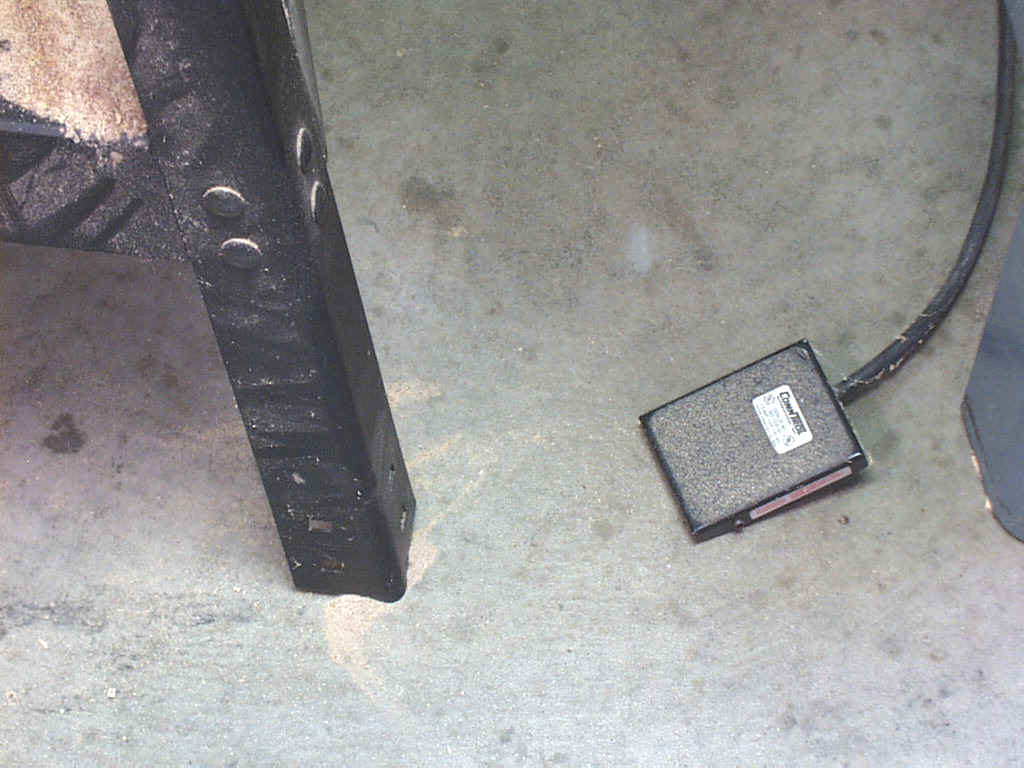

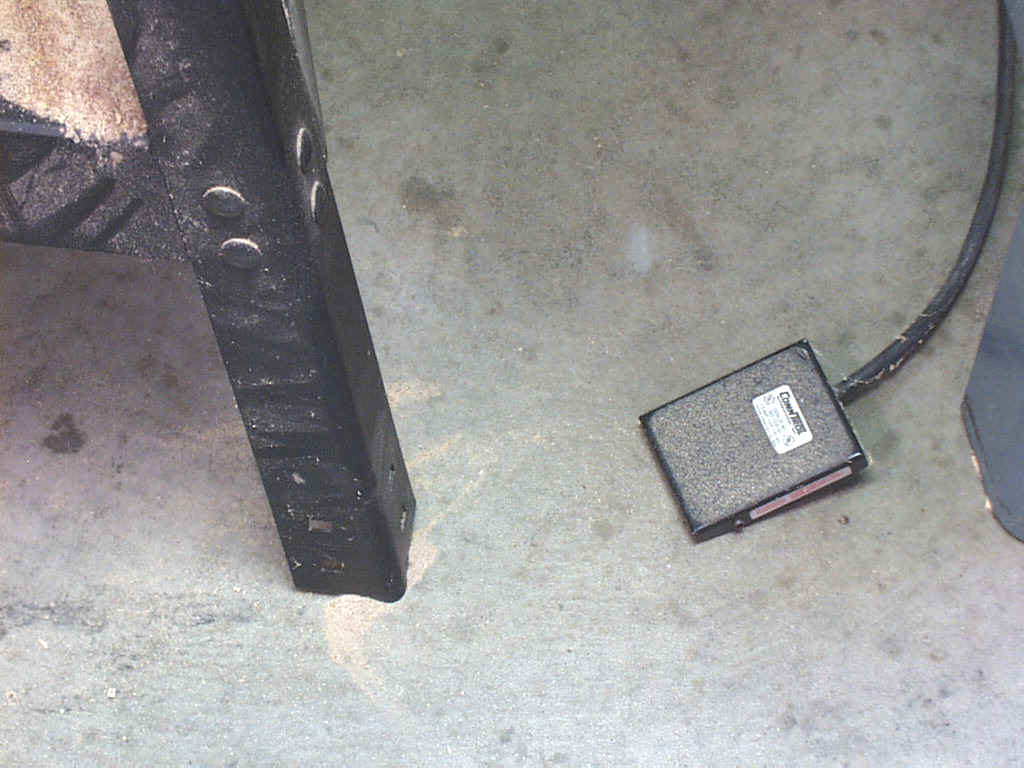

The saw is then going to be plugged into a 110 volt grounded outlet. For safety the saw should be unplugged whenever you change the blade or make any adjustments to the table. This is to assure the saw does not start while you have your hands and fingers around the arms and blade clamps on the saw. This is getting more important as many are now using the foot switch to operate the saw. Here we are concentrating on the blade going in right. We just can't see the clamp so we step around the side of the saw a little , and bang, we just stepped on the foot switch and started the saw. Not a very safe practice for sure. Had we unplugged the saw before starting the blade change this accident would have never happened.

Now before we even turn the saw on, we need to protect our eyes. If you have ever been around a saw when a blade breaks it is obvious why we need the eye protection. When those small blades break they sometimes break into many small pieces. And we have no way of controlling where they are going. On some of the saws with removable blade clamps, I have had the clamps fly out of the saw into the unknown. We only have one set of eyes and to loose either one of those could be a major disaster. I wear prescription glasses with safety lenses so my eyes are protected all of the time in the shop. There are many types of safety glasses, goggles and face shields available to protect your eyes. It is a matter of personnel choice which one you feel the most comfortable wearing. But wear one type for sure.

Some of the saws are very quiet when running. But while cutting wood the sounds of the cutting can become loud. Then there are saw that are noisy to start with. And some will use a shop vacuum as a dust collection system. So some type of hearing protection may be in order. There are sponge type earplugs, as the cheapest way to go. Then there are so many types of headphones that I could never describe them all. They range from styles that block part of the sounds , to types that will block almost all sound. Chose a style that coincides with the noise your sawing operation generates. There are custom molded ear plug that need to be fit by doctors. And some chose to use stereo headphones, so they can listen to music as they saw. I do not condone this practice as you can become too involved in the music and loose concentration on the sawing that your hands are doing. When you are sawing you need to concentrate on the saw just as you would any other power tool in the shop. Accidents can happen anytime, and they happen fast.

We are not ready to saw yet. There is still the problem with the dust in the air. Scroll projects seem to use some of the exotic woods for special effects. Some of these woods have very toxic effects from breathing the dust they generate. Even standard pine dust can respiratory problems. The thing we forget is that the Scrollsaw used a very fine blade. And those fine teeth generate fine sawdust that easily becomes airborne. If you cut for awhile you never see much sawdust. But wipe your hand across things in the area you were cutting in. You will find that a very fine dust has covered everything. That dust was in the air you were breathing before it settled. That dust can be inhaled right into your lungs, causing repertory problem. Maybe not today, but acculturated over time , it can build up in the lungs. And some of the dust is toxic and can cause irreversible damage to your lungs. So wear a dust mask, or control the airborne dust with other suitable methods. The cheap mask filters may work fine for most of your general cutting. But when cutting some of the more toxic exotic woods you may want to acquire a better grade of air filtering mask.

There are other ways to help control the dust. One is the use of an air filter system. There are commercial ones available that do a great job. There are also plans available to build you own from a furnace blower. With the proper filters these can be just as effective as the commercial ones.

A pleated furnace filter is mounted on the sides of the box for air intake.

A pleated furnace filter is mounted on the sides of the box for air intake.

Inside the box is a blower fan from an old furnace.

This unit is best mounted above and behind the saw so the airborne dust is pulled away from you.

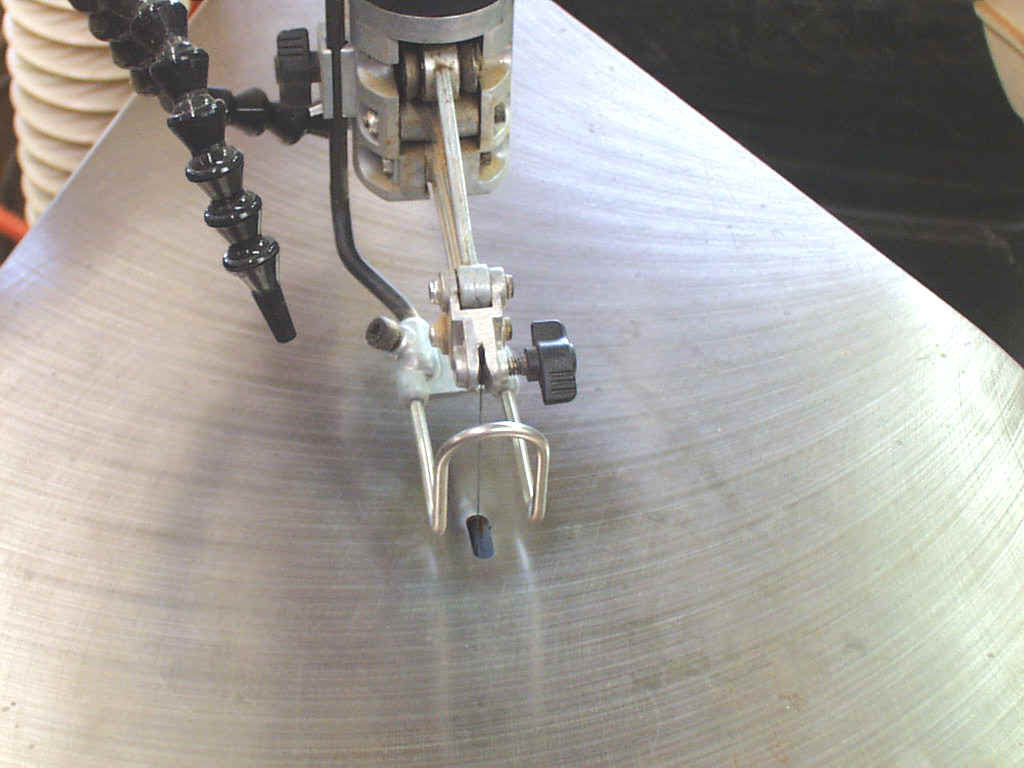

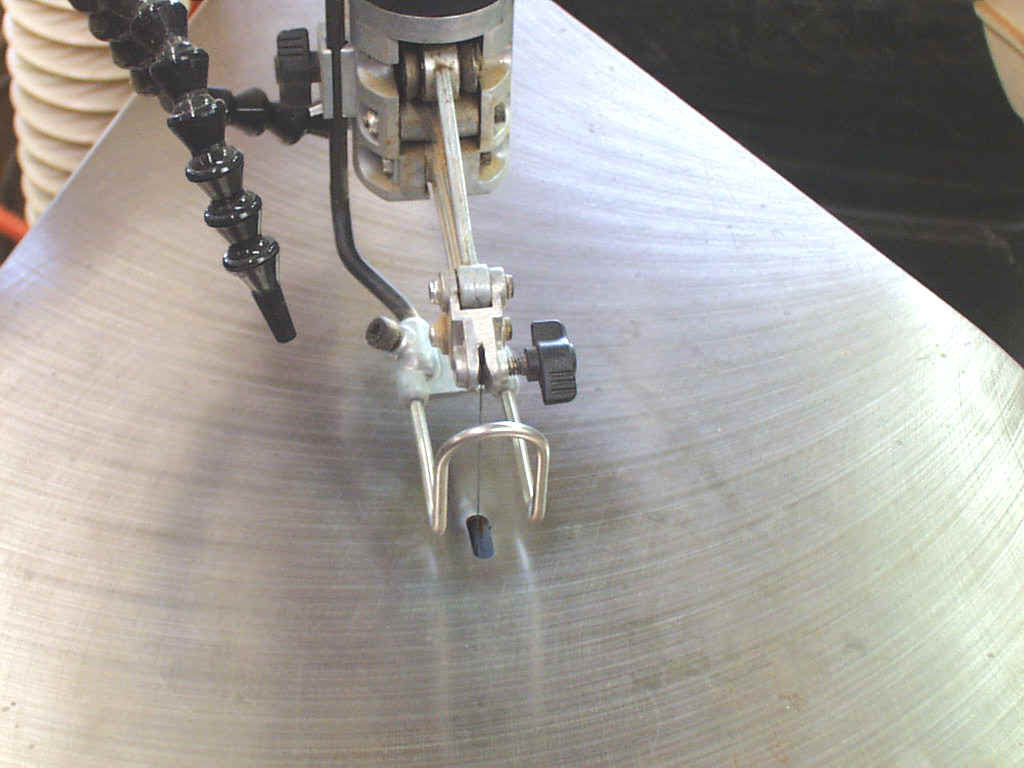

Now we finally get the safety features on the saw itself. The most visible is the hold down clamp. My guess is that 75% of the scrollers have removed the hold down because it always seems to be in the way. The clamp is required by safety mandates from the government. Therefore it should be used at all times for safety concerns. Properly used it holds the wood to the table and blocks most of the path to the blade that we could get a finger into.

Another safety feature found on the saw that sometimes gets removed is a lower blade guard. On some models of saw there is a guard in place around the lower blade clamp to protect you from getting your fingers between the arm and the bottom of the table. Sometimes this guard can be moved aside to gain access to the blade clamp. On other saws there are longer tools to use , making blade changing a little awkward. Even though many remove these awkward guards , we cannot condone it. Any guards that were on the saw from the factory should be left in place to be safe.

Another safety feature found on the saw that sometimes gets removed is a lower blade guard. On some models of saw there is a guard in place around the lower blade clamp to protect you from getting your fingers between the arm and the bottom of the table. Sometimes this guard can be moved aside to gain access to the blade clamp. On other saws there are longer tools to use , making blade changing a little awkward. Even though many remove these awkward guards , we cannot condone it. Any guards that were on the saw from the factory should be left in place to be safe.

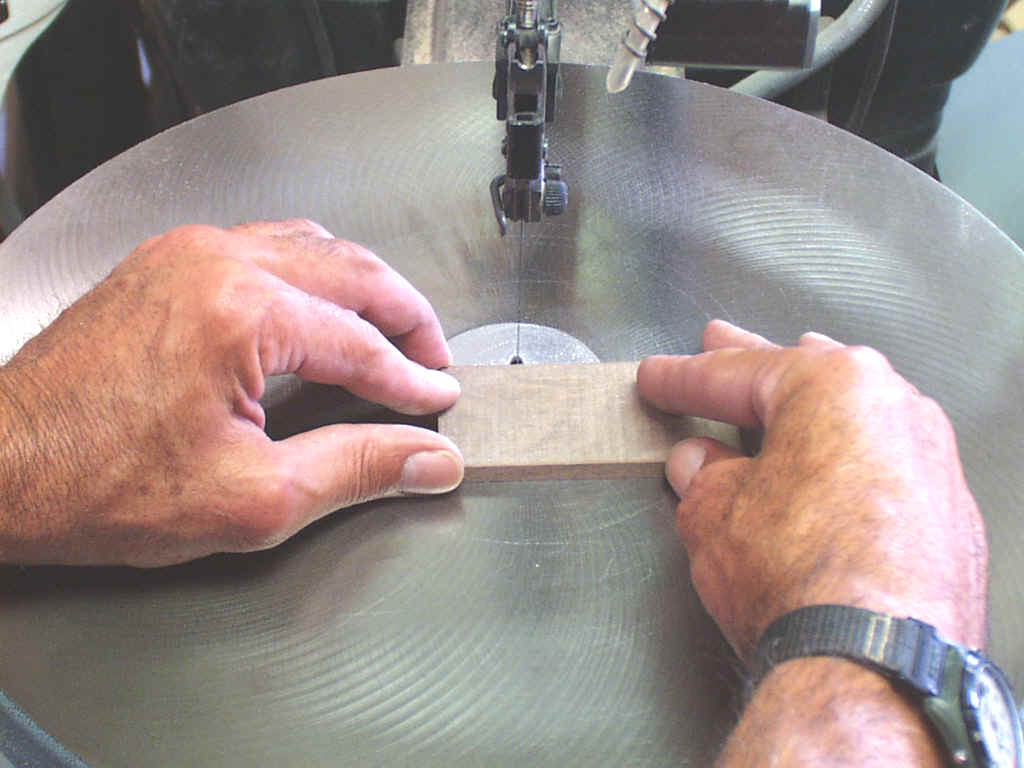

But for those who have chosen to remove the hold down there are some precautions to take. Keep your fingers to the sides of the blade.

NEVER place your fingers in the blade path.

NEVER place your fingers in the blade path.

Do not place fingers in front of the blade path. Especially when ripping narrow strips, because the blade can jump out of the cut and you will push your fingers into the blade before your reflex can respond. A very dangerous move.

If you do chose to remove the guard, keep your fingers a safe distance away from the blade and it's path. You will also need to apply downward pressure to the wood to hold it to the table.

A pleated furnace filter is mounted on the sides of the box for air intake.

A pleated furnace filter is mounted on the sides of the box for air intake.

Another safety feature found on the saw that sometimes gets removed is a lower blade guard. On some models of saw there is a guard in place around the lower blade clamp to protect you from getting your fingers between the arm and the bottom of the table. Sometimes this guard can be moved aside to gain access to the blade clamp. On other saws there are longer tools to use , making blade changing a little awkward. Even though many remove these awkward guards , we cannot condone it. Any guards that were on the saw from the factory should be left in place to be safe.

Another safety feature found on the saw that sometimes gets removed is a lower blade guard. On some models of saw there is a guard in place around the lower blade clamp to protect you from getting your fingers between the arm and the bottom of the table. Sometimes this guard can be moved aside to gain access to the blade clamp. On other saws there are longer tools to use , making blade changing a little awkward. Even though many remove these awkward guards , we cannot condone it. Any guards that were on the saw from the factory should be left in place to be safe.

NEVER place your fingers in the blade path.

NEVER place your fingers in the blade path.