P20 Repairs

I have ran the P20 a lot now and things are starting to come loose. So there are a few things to check out as regular maintenance items.

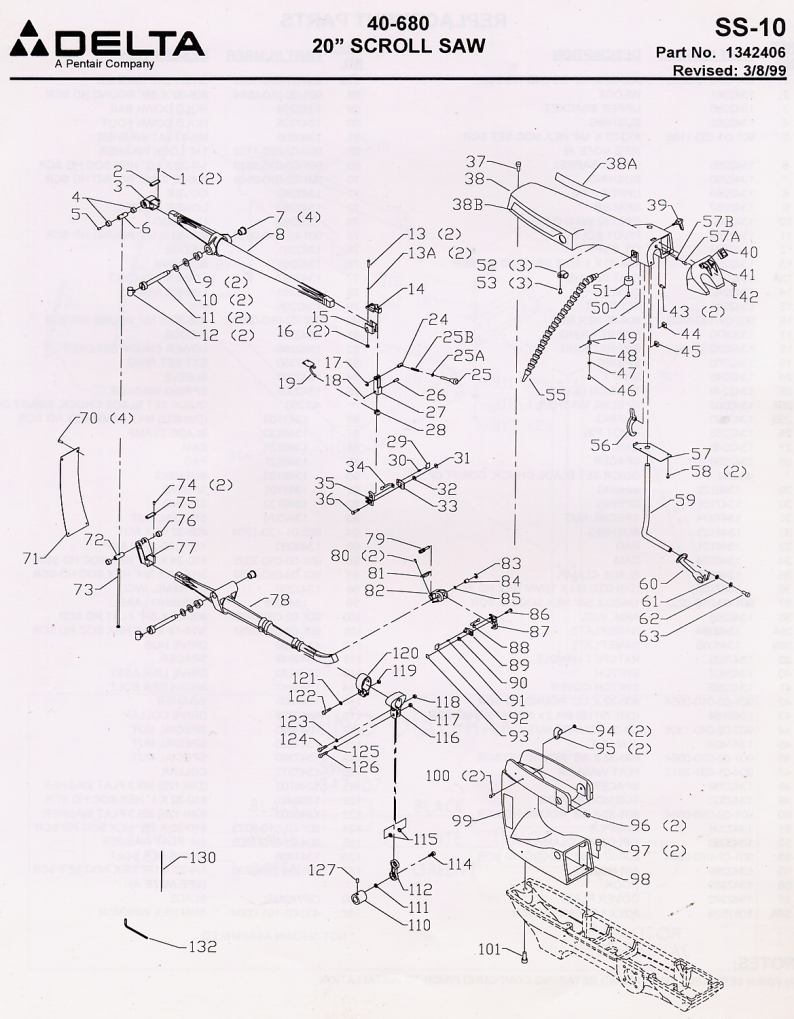

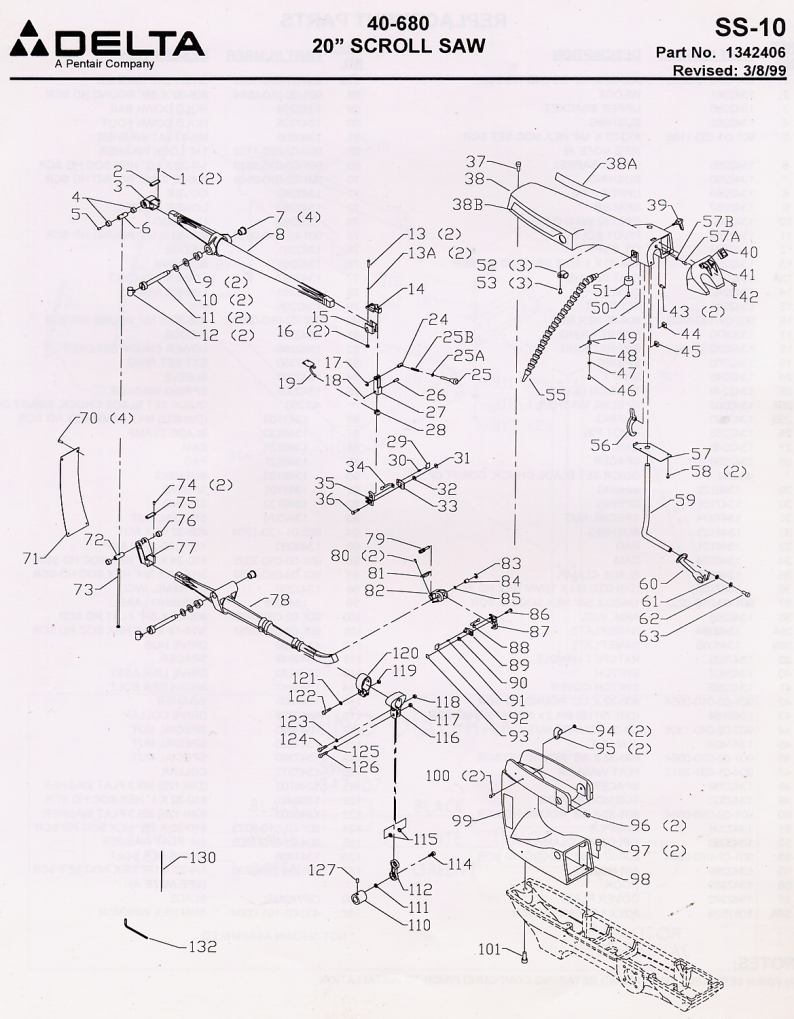

The spring ( parts # 46-49 ) fell out of my saw while cutting. So check the screw in that at times to be sure yours does not fall out. The screw has very few threads into the casting, don't try to tighten it too tight or it may strip the threads out.

The assembly of parts # 1-5 on the back of the top arm, the screws came loose and the arm started having a lot of play in it. This also caused a lot of blade breakage. There are 3 allen screws to remove to get the top cover ( part #38 ) off. Two from the front underside and one at the rear of the saw.

Now there are a couple of other things I learned. If the tension lever is hard to push back, really dragging with that metal to metal screech. I used graphite to lube it. What a difference. Smooth as glass now. The graphite is purchased as a dry lube for locks, so look around where they sell keys for cars and doors to find it.

The other thing I found is that the belt can be ran on a step pulley setup to get more variety of speeds from the saw. For example the belt can be on the far left hand pulley of the motor and the second from the left pulley on the saw. This gives a lot more speeds to chose from on the saw. And I have not had to readjust the belt or anything to get it to work. Have not had a problem with the belt jumping off the pulley either.

P20 Belt

More on replacement belts:

I

suggested going to MSC

http://www1.mscdirect.com/CGI/NNSRIT?PMAKA=75750182

part number 75750182

or Mcmaster carr for o-rings of this size. There is also a belt system that

uses small barbed connectors to join the ends of a belt with a hollow

center. They can be cut to any length. http://www.mcmaster.com/

If

you can't make out the specs from my jpeg they are as follows... Durometer

is 85 shore on D scale Yellow in color Circumference is 16.5 inches from the

picture the diameter is 5.25 inches the thickness is 0.25 and the last one

is R2.6257 Hope this helps

Or a sewing machine belt might

work, just take your old belt into the sewing machine parts dept.

Blades are too long for the saw