Long Stem Goblets

Our Woodturning club meeting demo was on turning long stem goblets. So like normal I had to come home and try it. Of course just a long stem was not enough of a challenge, I had to make them with excentric long stems. This is the first day of turning on long stems. I really want to try to make one longer, maybe 30" tall. If I can get it done I will post pictures.

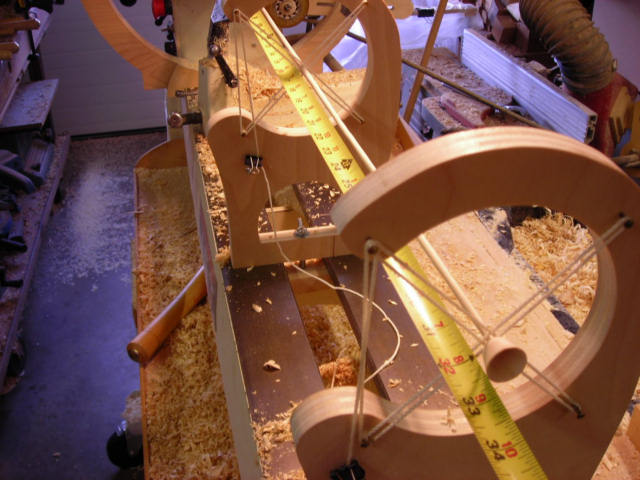

Well I have started on a longer one and am taking a few pictures along the way. This started a a peice of pallet lumber, I think cottonwood. I cut it down to about a 1" square X 35" long so it would fit the lathe bed. Then I chucked it up between centers and rounded the first section of maybe 6" long. Then I put my homemade steady rest onto the shaft and used a 1/4" spindle gouge to make the cup at the top.

From there I have used an oval 1" skew to make the shaft. Here is the first picture of the progress.

Well it came time to move the steady rest and I did not have the wood rounded out. The theory was to leave it square for more strength, but I don't think I will do that again. So to get by I am just using the skew to round it without any tool rest. Now this teaches you how to hold a tool against your side and keep it steady. So far it has worked, but I would not really recomend it as the prefered way.

Anyway as you finsih up about 4" then you move the steady rest down and the tool rest into position and do it all over again.

As you see I set up the homemade string steady rest after about 8" of stem was done. The string steady will stay there on the end through the whole process. I will use another string rest at about 16" to steady the center as I get farther along. As I use the skew to make the shaft I will hold fingers behind the skew to steady the shaft a little. Then I sand as I work down the shaft. I cut about 2" then sand then start cutting the next 2" of shaft. I never try to work on anything over 4" out from the main block of wood, so you need to get the shaft right before you move on as you go.

Still more progress.

And a little more. But still not out of wood.

Now I am to the chuck, so I guess I used the whole peice of wood.

Finished !!!!

The idea for the long one with the beads came from these sites.

http://www.woodturningonline.com/Turning/Projects/trembleur.html

http://www.chicagowoodturners.com/gmcmurrayoct2001.htm

To make mine I used the skew to make the straight sections and the beads and disc. For some of the real tight areas I used a 1/4" skew that came with my mini set of tools. The tall ones are just over 33" tall. The bottom right excentric one is about 14 1/2" tall.

Tried one with a thin stem. It actually measures .09 or about 3/32".

After all of these turned successfully, I finally broke one. I was going back and trying to clean up the bottom of the disc area with a 1/4" skew and had a catch.

I had even tried the chatter tool on this one.

I want to show the string rest a little closer. When I first started using one I understood the way to wrap the string was like this.

But I found that by looping over each peg a lot more sercure steady can be made. This does not allow the stem to move in any direction and seem to reduce ay wobble you may have had with the first way. Go from the nail up around the stem and back to the nail, then over to the next nail around the stem and back to the nail. Notice how I have used a paper binder clip to lock the end of the string.